Apple has declared that it is intensifying its efforts to incorporate more recycled materials in its products. This includes a new goal for 2025 to use 100% recycled cobalt in their batteries and the commitment that all magnets in their devices will use entirely recycled rare earth elements and all Apple-designed printed circuit boards will use 100% recycled tin soldering and 100% recycled gold plating.

Apple has made substantial progress by using over two-thirds of aluminium, almost three-quarters of rare earth, and over 95% of tungsten in its products from 100% recycled material as of 2022. This advancement gets Apple closer to its long-term goal of manufacturing products with only recycled and renewable materials. Also, it supports its 2030 objective of achieving carbon neutrality for every product.

The company has set a new target to use 100% recycled cobalt in all its batteries by 2025 and plans to use entirely recycled rare earth elements for the magnets in its devices by the same year. In addition, all printed circuit boards will use 100% recycled tin soldering and gold plating.

The company has made progress using certified recycled rare earth elements, increasing usage from 45% in 2021 to 73% in 2022.

Apple has expanded the use of this material across its devices, including in all magnets found in the latest iPhone, iPad, Apple Watch, MacBook, and Mac models.

Since magnets are the largest use of rare earths in Apple products, the new 2025 target means nearly all rare earths used by Apple will soon be 100% recycled, bringing the company closer to achieving its 2030 goal of making every product carbon neutral.

Apple responsibly obtains primary minerals and maintains its supply chain’s highest human rights and environmental standards. The company was the pioneer in the electronics industry to publish a list of cobalt and lithium refiners in its battery supply chain, starting with cobalt in 2016 and lithium in 2020. In 2017, Apple also created a map of its supply chain for rare earths. Since 2015, every identified smelter and refiner for tin, tungsten, tantalum, and gold has undergone independent third-party audits.

Apple has given special attention to 14 specific materials in their move towards using recycled and renewable materials, which comprise almost 90 per cent of the materials used in their products. These materials were chosen based on their environmental, human rights, and supply chain impact. The 14 materials include aluminium, cobalt, copper, glass, gold, lithium, paper, plastics, rare earth elements, steel, tantalum, tin, tungsten, and zinc.

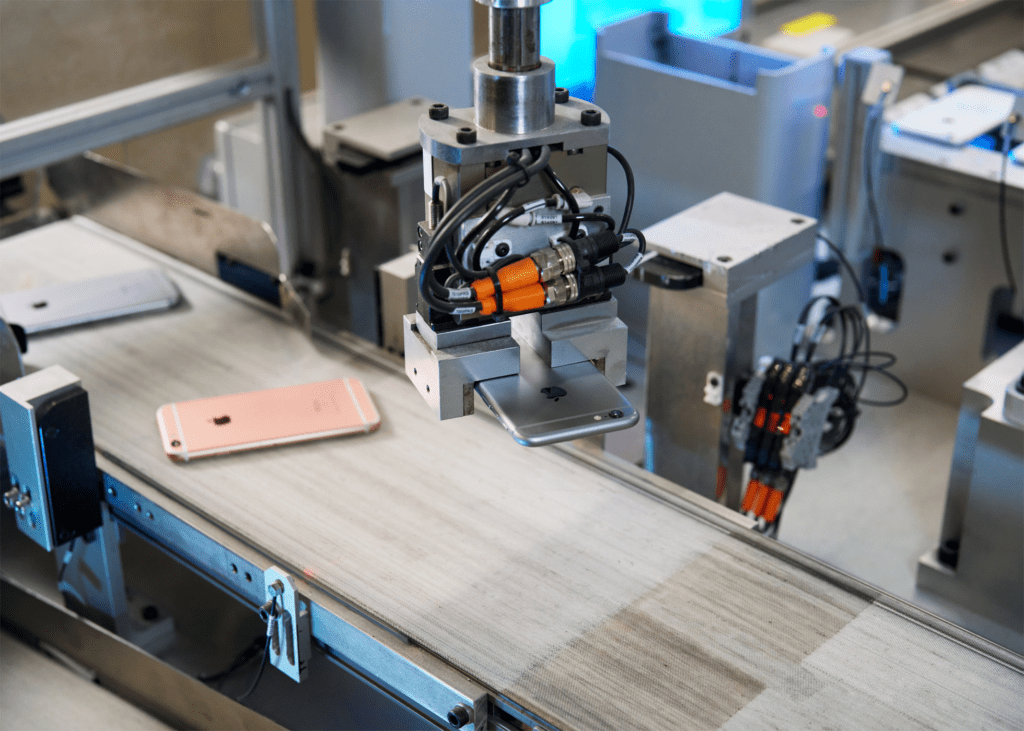

Daisy is a robot created by Apple that disassembles iPhones and separates their batteries from other components, making it easier for speciality recyclers to recover materials like cobalt and lithium. Daisy has helped recover over 11,000 kilograms of cobalt from recycled batteries since 2019. Another robot, Dave, deployed in China, helps recover rare earth elements by disassembling Taptic Engines. To further drive innovation in recycling and disassembly, Apple has also introduced augmented reality (AR) systems to recycling partners that guide the disassembly of devices like MacBooks and iPads.

The company has also published Apple Recycler Guides to help global recyclers maximize material recovery while ensuring the safety of workers. As Apple moves towards greater use of recycled and renewable materials in its products, it is also working towards its goal to be carbon neutral across its entire supply chain and the life cycle of every product by 2030.