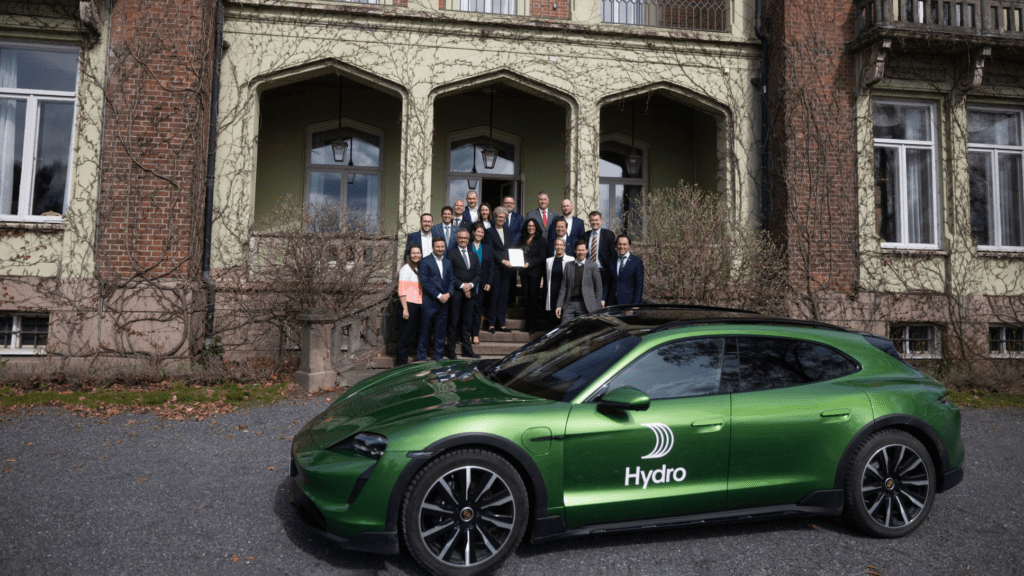

Porsche and Norsk Hydro have formed a partnership to reduce the carbon footprint of Porsche car models using low-carbon aluminium and extrusions from Hydro, and to collaborate on creating a sustainable battery value chain.

Hydro will provide Porsche with low-carbon aluminium with a low CO2 footprint, reducing emissions from mine to metal, enabling Porsche to reduce the footprint of aluminium in future vehicle projects to around 3.5 kg of CO2 per kg of aluminium used by 2025, which is approximately 60% lower than the average primary aluminium consumed in Europe currently.

Hydro aims to supply Porsche and Porsche’s component suppliers with aluminium targeting CO2 neutrality in 2030. The companies will work on a roadmap to recycle battery materials in Europe, building efficient closed-loop solutions for Porsche’s EV batteries. The first feasibility results of joint battery recycling are expected in 2025.

“To reduce global warming, we need to decarbonize energy systems, produce for circularity and recycle resources already in use. Aluminium is a key enabler in the green transition, but supply chains must become emission free. The industry needs to partner up to make this happen and we are pleased to be able to work with a pioneer like Porsche in our common task to create a nearly carbon-free car,” says Hilde Merete Aasheim, President and CEO of Hydro.

“Porsche is working towards a net carbon-neutral value chain of our vehicles in 2030. Aluminium and materials for battery production play a key role in our sustainability strategy. With Hydro’s aluminium we aim to substantially reduce CO2 emissions deriving from this important material,” says Barbara Frenkel, Executive Board Member for Procurement at Porsche AG.